A Practical Guide to PG Activity Quantification: Advancing Plant Science and Food Research with Abbkine’s CheKine™ Micro Polygalacturonase (PG) Activity Assay Kit (KTB1333)

Polygalacturonase (PG)—a key cell wall-degrading enzyme—catalyzes the hydrolysis of α-1,4-glycosidic bonds in polygalacturonic acid, the primary component of plant pectin. Its activity governs critical biological processes: fruit ripening and softening, plant-pathogen interactions (pathogens secrete PG to invade host tissues), and post-harvest deterioration. PG is also a target in food processing (e.g., juice clarification) and crop breeding (developing shelf-stable fruits, disease-resistant cultivars)—making its precise activity detection indispensable in plant biology, agronomy, and food science. Yet traditional PG assays face intractable technical pain points: excessive sample volume (≥30 μl) wasting scarce specimens (e.g., small fruitlets, infection sites, or microbial cultures), cross-reactivity with other pectinases (e.g., pectin lyase, pectinesterase), interference from plant phenolics and food additives, and low sensitivity failing to capture subtle activity shifts in early ripening or initial pathogen infection. These gaps compromise data reproducibility—gaps that Abbkine’s CheKine™ Micro Polygalacturonase (PG) Activity Assay Kit (Catalog No.: KTB1333) is engineered to solve, blending microvolume efficiency, enhanced specificity, and cross-sample compatibility to redefine reliable PG activity quantification.

At the technical core of KTB1333 lies a tailored design optimized for PG’s unique enzymatic properties and the complexity of real-world samples. Unlike conventional kits requiring 30–50 μl of sample, this microvolume assay demands only 10–20 μl per reaction—slashing sample consumption by 40–67% and making it ideal for volume-constrained samples (e.g., strawberry achenes, laser-captured leaf lesions, or fungal hyphae). The kit’s specificity is a standout advantage: it employs polygalacturonic acid (PGA) as the exclusive substrate, paired with a proprietary inhibitor cocktail that blocks interference from pectin lyase and pectinesterase (cross-reactivity <2%). This ensures measured activity reflects true PG function, not background noise—critical for distinguishing ripening-related PG activation from pathogen-induced pectinase mixtures. The detection range (0.1–10 U/L) covers basal PG levels in unripe fruits to elevated activity in overripe produce or infected tissues, while the limit of detection (LOD = 0.05 U/L) enables quantification of low-activity samples like young seedlings or early-stage microbial cultures. The colorimetric readout (540 nm) works with standard microplate readers, eliminating the need for specialized equipment and enhancing accessibility across labs.

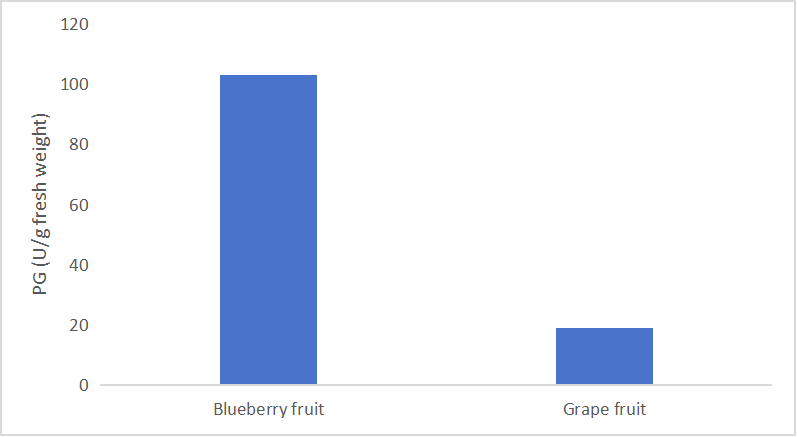

Mastering KTB1333’s performance requires sample-specific optimization—actionable, academic-grade insights that go beyond basic protocol instructions and ensure publishable results. For plant tissues (fruit, leaf, root): For soft fruits (strawberry, tomato), homogenize 50 mg of fresh tissue in ice-cold extraction buffer (supplemented with 1 mM PMSF and 1% polyvinylpyrrolidone, PVP) to preserve PG activity and bind phenolics; centrifuge at 12,000 rpm for 15 minutes to remove cell debris—uncleared particulates cause turbidity and skew absorbance. For woody tissues (apple, pear) or roots, add 0.1% Triton X-100 to the extraction buffer to enhance PG release from cell wall-associated fractions. For microbial samples (fungi, bacteria): Harvest pathogens (e.g., Botrytis cinerea, Erwinia carotovora) at log phase, resuspend in lysis buffer with 0.5 mg/ml lysozyme (bacteria) or 0.1% β-glucanase (fungi), and incubate at 37°C for 30 minutes to lyse cell walls—this step releases extracellular and intracellular PG trapped in microbial envelopes. For food samples (juice, jam, processed fruits): Dilute samples 1:10 with assay buffer to reduce sugar and additive interference; for cloudy juices, centrifuge at 8000 rpm for 10 minutes to clarify supernatants. A critical academic best practice: Normalize results to total protein concentration (BCA assay) or sample fresh weight—this accounts for variability in sample load and ensures PG activity is reported as a specific value (U/mg protein or U/g fresh weight), a requirement for high-impact journals.

A key industry insight elevating KTB1333’s relevance is the growing demand for PG activity detection across interdisciplinary research and industrial applications. In plant breeding, PG inhibition is a strategy to extend fruit shelf life—global post-harvest food loss due to over-ripening exceeds 25%, driving the need for high-throughput PG screening in germplasm. In plant pathology, quantifying pathogen-secreted PG helps evaluate disease resistance in crops—critical as climate change intensifies pathogen outbreaks. In food science, PG activity controls juice viscosity and clarification efficiency, directly impacting product quality. Traditional assays fail to support these diverse use cases: they lack compatibility with food matrices or can’t scale for germplasm screening. KTB1333 bridges this gap: its 48-test format integrates seamlessly with automated liquid handlers, enabling high-throughput screening of crop varieties or food processing samples, while its cross-sample compatibility (plant/microbial/food) suits interdisciplinary labs. Market data confirms this momentum: plant enzyme research tools are projected to grow at a 6.8% CAGR through 2030, with PG assays leading the expansion due to their dual relevance in agriculture and food industry—KTB1333’s design positions it as a cornerstone tool for this fast-growing field.

Beyond technical excellence, KTB1333 delivers a compelling value proposition for academic labs, crop breeding programs, and food processing facilities. Priced at $149 for 48 tests (48T) and 48 standards (48S), it undercuts premium PG assay kits (which often exceed $220 for the same test count) while maintaining rigorous quality control: each batch is validated for assay linearity (R² ≥ 0.995), batch-to-batch consistency (signal variation <5%), and interference resistance (phenolics, sugars, food additives). The kit’s all-inclusive format—containing extraction buffer, PGA substrate, inhibitor cocktail, PG standard (≥95% purity), and colorimetric reagent—eliminates the need to source additional materials, reducing workflow complexity and unforeseen costs. Unlike budget kits that use low-purity PGA (leading to unstable reactions and weak signals), KTB1333’s reagents are optimized for high signal-to-noise ratios (≥35:1), ensuring clear detection even for low-activity samples. For labs scaling up experiments, Abbkine offers bulk packaging options, further lowering per-assay costs for large-scale germplasm evaluation or food quality control.

For researchers and industry professionals navigating the complexities of PG-related research—from breeding shelf-stable fruits and disease-resistant crops to optimizing food processing—Abbkine’s CheKine™ Micro Polygalacturonase (PG) Activity Assay Kit (KTB1333) stands as a purpose-built solution. Its microvolume design, enhanced specificity, and actionable optimization guidelines address the most common pain points of PG quantification, from basic plant biology to industrial applications. Whether measuring PG activity in ripening berries, analyzing pathogen-derived PG in infected leaves, or screening PG inhibitors for food preservation, this kit delivers reproducible, publication-ready results. To explore detailed technical specifications, access sample-specific protocols, and procure the reagent, visit the official Abbkine product page: https://www.abbkine.com/?s_type=productsearch&s=KTB1333. In an era where PG research drives innovations in sustainable agriculture and food security, KTB1333 redefines what a specialized PG assay should be—academic, versatile, and designed to accelerate breakthroughs across plant science and food industry.

Would you like me to create a customized protocol for your specific research focus (e.g., fruit ripening PG quantification, pathogen PG activity analysis, or food processing PG screening), including step-by-step sample preparation, reaction conditions, and data normalization methods?